| Details………. Homemade Honey Comb Press …….latest news first ………chronological evolution of the design of a honeycomb press that delivers a very high pressing force with no manual effort………. |

||||

|

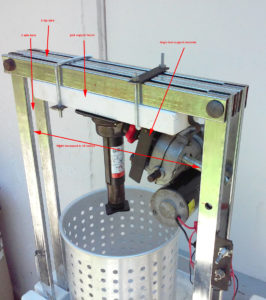

Update 9/1/2022 – The honeycomb press describe below is being retired. With the increased number of NaplesBees hives in the apiary, it was advantageous to move to using a small extractor in order to be more efficient at honey harvest time. For the last few honey harvests that have been done, a 4 frame speed controlled spinner extractor was used. Update 11/15/2019 -The honeycomb press was used 3 times for the 2019 honey harvests. Almost 550 pounds of honey was harvested from the NaplesBees hives and all of it was soley processed by using this electrically controlled press. It is extremely efficient in making the honey and wax harvesting easier. The compressed honeycomb left over is melted down and cast in to one pound blocks.  25 pounds of one pound blocks of beeswax recovered from a few recent 2019 honey harvests using the updated honeycomb press. Update 5/4/2018 – The new and improved honeycomb press got its first real workout with use in our largest ever honey harvest (305 pounds of honey). It was a resounding use success with no issues and I was able to exert an extremely high pressing force and squeeze out every drop of honey from the comb. Because the pressing force can be so high, the only additional improvement that I could think of would be obtaining a basket with many more and smaller holes. If anyone knows where such a basket like that could be obtained, let me know. Update 8/12/2017 — After our latest honey harvest, which up to this date was the largest I have ever had, I decided to make improvements to my Homemade Honey Comb Press by making it even more robust and slightly larger. I discovered that the addition of the motor/gear to the operation allowed me to quickly apply much more force in squeezing the comb which resulted in showing some improvements would be needed to the press framing. In addition, the width of the side bars spacing was needed to be increased for easier access. The resulted much improved motorized honey press is now complete. Changes to the press consisted of a wider bar spacing and base (16 inches), doubling of the vertical bar supports, additional bars added to the top crossbars, stronger jack mounting and improved motor mounting. This press will better stand up to the much faster and higher pressing force we can exert with the motor/gear arrangement driving the jack. If this information helps you on making your own honeycomb press, share with me any improvements you come up with.

Update 5/22/2017 — I have “motorized” the homemade honey press by adding an electric motor/gear to operate the jack effortlessly. I can switch select up/down and control the speed of movement. This is a major improvement and will take all the work out of manually operating the original Homemade Honey Comb Press that is described in detail below. The motor/gear assembly was a junk unit that was originally used to operate a slide out in an RV. It has a 12 volt motor and reduction gearing and a worm gear to provide plenty of torque to operate the jack. |

||||

|

(click on picture for a larger view) |

||||

|

|

||||

| I made the plunger top out of 3/4 inch plywood with a 2X4 reinforcing block. Additional 2X4 blocks were made to be used as spacers during the pressing operation. | ||||

| A close up of the jack above the strainer basket. I use a paint strainer bag of around 600 microns. Most pollen rarely exceeds 100 microns, so all the pollen goodness passes through the strainer and remains in the honey. The strainer bag now inside the basket holds the raw honey comb that is poured or ladled in from the 5 gallon collection bucket. When the basket is about full, I fold the strainer bag over it and place the round press top down into the basket.

|

||||

| Above shows the plunger top and a spacer block ready to be squeezed by the jack. I found it most effective to advance the jack slowly until the honey starts to flow out of the strainer basket into the pan, let it rest for a minute, and then apply more pressure. Keep repeating this until at the very end, no more honey is coming out. It is amazing how “dry” of honey the circular block of compressed comb wax is once you are done. The resultant honey is completely free of a particles because of the use of the paint strainer bag and the honey is ready for bottling. |

||||